Resinity for Food Manufacturing

Reliable food safety compliancy: from kitchen to customer!

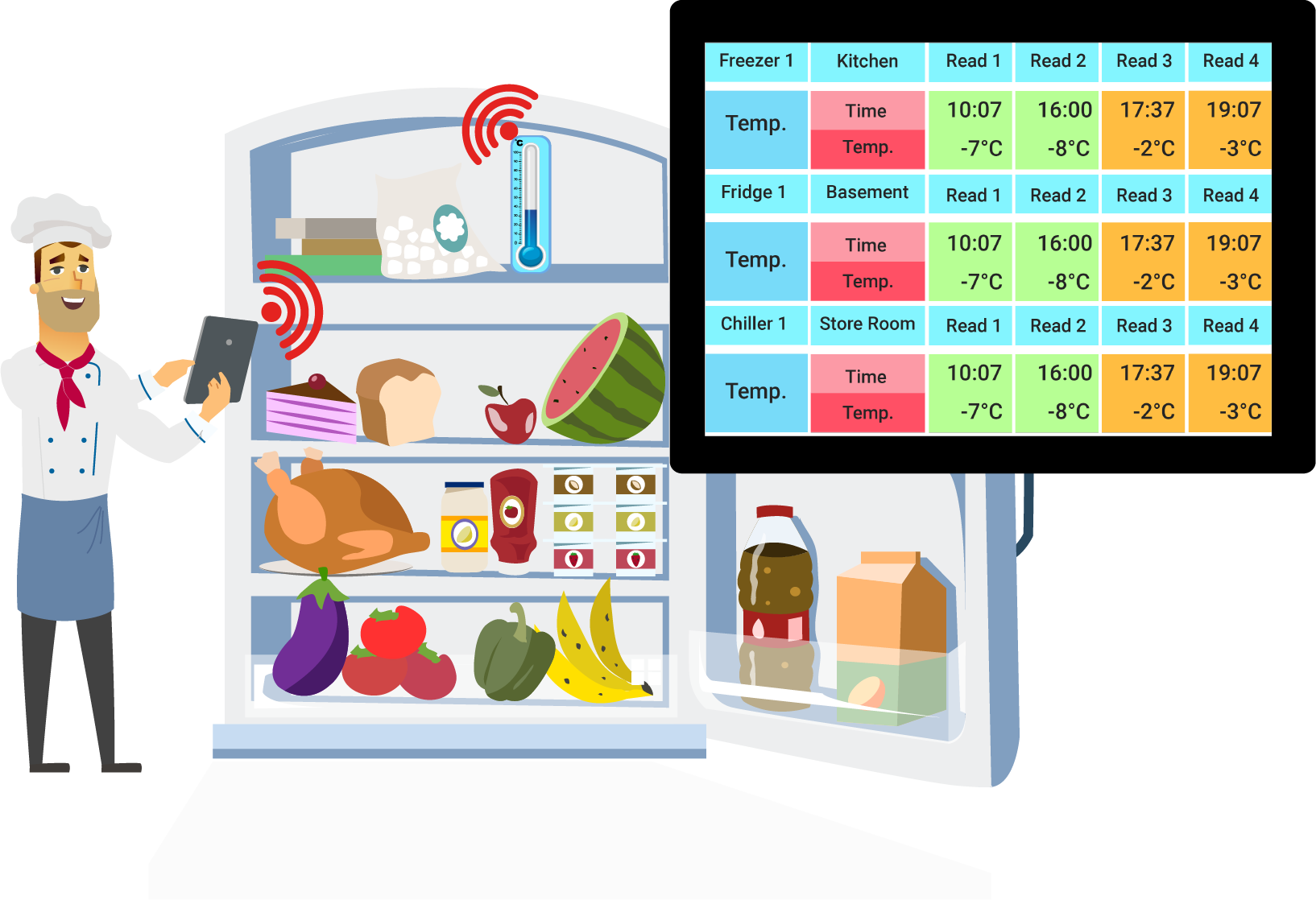

- Record and track food and equipment temperatures across the manufacturing process via smart Bluetooth technology; ensure food is kept at the right temperature at all times, and maintain your fridge and freezer performances

- Be alerted when there is a failure in the manufacturing process; whether a fridge shuts down, or food temperatures aren’t up to standard, you will be the first to know and be able to find a solution quickly

- Manage staff production standards; ensure all of your staff are following safety regulations with staff monitoring in accordance with the production process

- Keep your production line up to standard with the latest HACCP, BRC, and ISO regulations – available with integrated checklists for Checkki

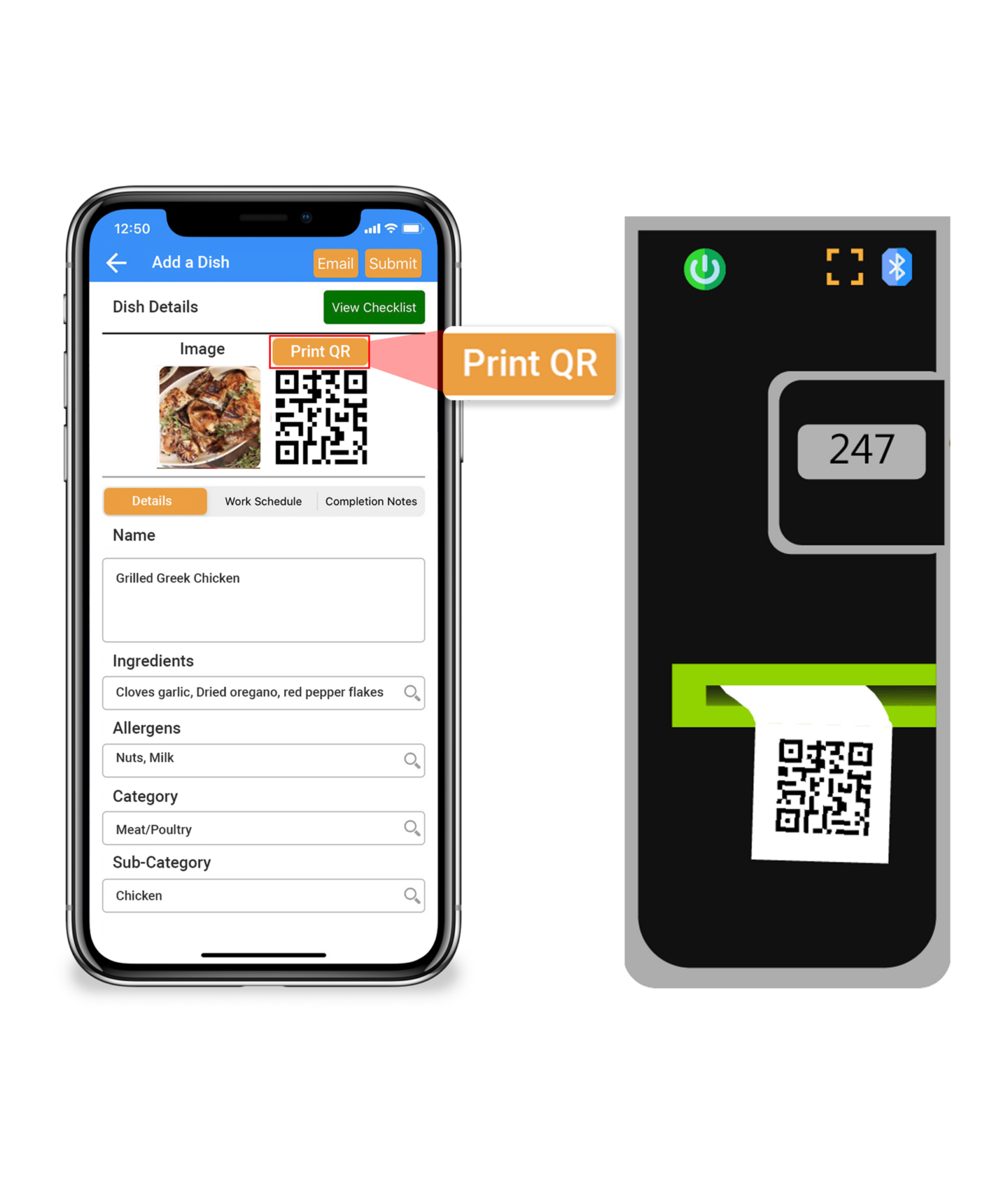

Track and record your dish details

- For managers and staff; log the details of each dish with innovative QR-code technology, including the production process, imagery, ingredients, allergies and more!

- For customers; use QR-codes on menus to discover dish ingredients, allergens, and calories details, allowing them to make informed and safe decisions about what they eat

Staff Management

- Attendance; biometric (facial recognition) clocking-in/out system with personalised on-screen messages for each staff member, track attendance patterns, pay for hours worked efficiently, manage time-off and annual leave

- Rota Scheduling; automatically schedule your rota based on staff availability and skills, staff updated with their rota or any changes via text message to ensure clear and consistent internal communications

- Task Assignment; create daily briefs for staff members to follow in accordance with their skill-level and role, create notes for new-starters, allergies, staff attendance, special reservations etc.

- Digitally record accidents and incidents; staff can report to a manager, and manage any required actions, follow-ups, or reports

Stock Management

- Use QR-code technology to manage your stock levels; allow staff to place orders digitally, record deliveries and restocks with QR-code technology, know what’s being delivered and when, manage what stock is being used and its levels in real-time, pay for what is actually delivered i.e., never pay for missing stock!

Premises Management

- Manage your assets; track your assets such as kitchen or manufacturing equipment with QR-codes and RFID-tags, log repair and use history, manage who has your assets and why, receive repair reports after every contractor repair

- Report repairs; staff can report repairs needed throughout your premises by scanning equipment’s individual QR-codes, which are then forwarded on to approved contractors who will perform the repair and provide photo evidence of completed tasks

- Manage keys; tag and track your premises and equipment keys with printable QR-codes, staff can check keys in and out using a digital signature system, track the keys use and whereabouts, find lost keys with a GDPR-compliant return system

Delivery Management

- Ensure quick, efficient, and professional delivery services; provide live delivery tracking for customers so they know when to expect a delivery and who is delivering their food, use QR-code Smart Label technology to create e-receipts for drivers so they can get up-to-date delivery information and provide customers with dish details and travel conditions, plan and schedule deliveries and driver routes for efficiency

From Farm to Fork, Everything Managed, Tracked and Traced.

Want a personalised quote?

Our unique pricing calculator can work out the best price for you

Who is Resinity for?

RESTAURANTS

Make sure your restaurant can boast a 5-star Food and Hygiene rating by using checklists in Checkki.

Increase food safety and always pass food inspections.

FOOD MANUFACTURERS

Use Resinity to ensure complete traceabilty for Food Manufacuring, from the farm to your factory. Manage and complete all ISO, HACCP, BRC standards checklists from one place. Keep staff accountable about their performance and attendance. Keep track of everyone’s attendance & punctuality and set alerts if they are late too often. Increase efficiency in business processes by letting Resinity manage all the complaints and incident/accidents reports. Use live temperature and humidity trackers to reduce waste while transporting materials for manufacturing.

FOOD SUPPLIERS

A perfect solution for food suppliers with a system for live tracking temperature and humidity levels, along with accelerometer readings, for individual items, boxes and pallets. Increase traceability for all your products. Keep staff accountable about their performance and attendance and set alerts if someone is late too often. Manage maintenance reports, incidents and accidents all from one place.

FOOD STORAGE

Organise staff and keep them safe by managing your production centre, providing informative task lists and tracking the progress of your stock and deliveries.

CARE INDUSTRY

Make sure your food is completely traceable along with the temperature it was kept at during transport. Also keep your staff accountable for attendance and punctuality and more.

FOOD DISTRIBUTORS

Have the peace of mind knowing that all your items, anywhere in the vehicle, are getting their temperature and humidity tracked so you know that every item in the truck has been in its required condition. Keep staff accountable for handling the items, their punctuality and attendance by using accurate facial recognition software. Decrease waste by reassuring customers that all your items are compliant by using Resinity.

HOSPITALITY

FOOD WHOLESALE

Keep yourself and the customer happy by keeping a complete trail of your food and the conditions it has been in (including temperature, humidity and if it has been dropped) using Smart labels. Also keep your staff accountable in attendance, punctuality and handling items. Fulfill all criteria for being compliant with ISO, HACCP and BRC standards using one app.

BUFFET & HOT HOLDING

Make sure your buffet restaurant can boast a 5-star Food and Hygiene rating by using checklists in Checkki.

Increase food safety and always pass food inspections.